Are they are too large?

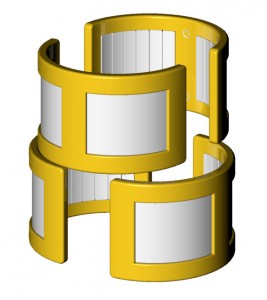

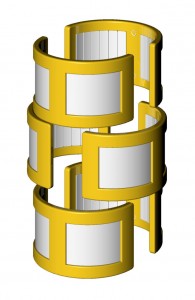

Although this looks like a good fit, it’s not. This filter diameter is 4.4”. CT4.9s require a minimum diameter of 4.5”. That 0.1” in diameter difference prevents the FilterMags from making complete contact to the outside wall of the oil filter.

An obvious indicator that the FilterMags are too large for the filter is when two FilterMags are butting against each other, creating a diameter larger than the filter. This creates a gap between the FilterMags and the filter.

This 0.1” gap is very significant. It will severely limit the FilterMag’s effectiveness, and reduce the magnetic bond securing the FilterMags to the filter.

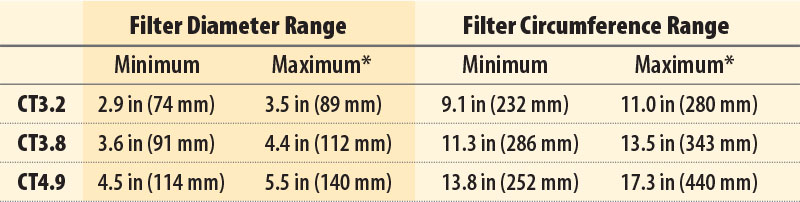

Refer to How to Measure the Filter Diameter in this section.